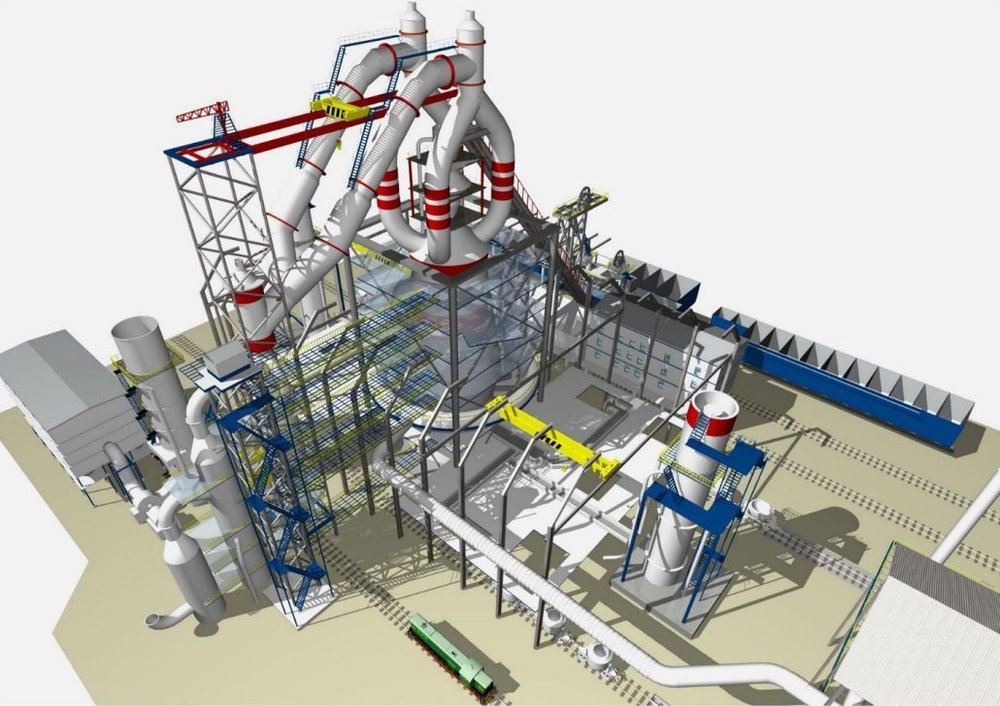

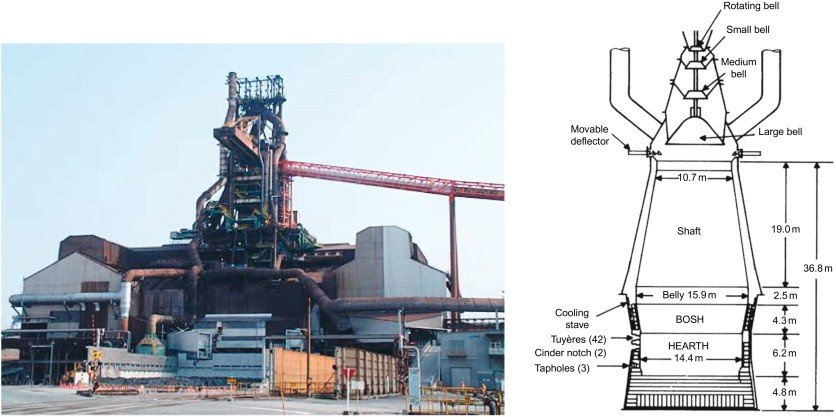

The Blast Furnace Maintenance Project for One Steel Whyalla focused on developing comprehensive maintenance planning and step-by-step instruction drawings to streamline and enhance furnace maintenance processes, such as replacing bricks and liners. This project was executed in collaboration with L.E. Otten, a renowned engineering consultancy.

Project Deliverables and Scope

-

Maintenance Planning Drawings: Detailed schematics outlining the maintenance process, including:

- Required tools and equipment

- Safety protocols

- Sequenced operations for efficient task execution

- Component locations, including bricks and liners

- Step-by-Step Instruction Drawings: Visual guides with detailed instructions to ensure tasks are performed correctly and safely.

Technical Expertise and Execution

Creating these specialized drawings required advanced technical knowledge of blast furnace operations, maintenance procedures, and safety standards. The project also emphasized effective communication with maintenance teams to ensure the deliverables were precise, user-friendly, and practical.

Key Achievements

- Delivered all drawings on schedule and within budget.

- Improved maintenance accuracy and efficiency.

- Reduced operational risks and errors.

- Enhanced safety measures through clear procedural guidance.

- Minimized maintenance time and costs while increasing overall quality.

Workflow and Methodology

The project encompassed several critical stages:

- Analyzing blast furnace operations and maintenance requirements.

- Identifying and documenting specific maintenance tasks.

- Incorporating stringent safety compliance measures.

- Collaborating with maintenance personnel for input and feedback.

- Preparing, reviewing, and finalizing detailed drawings.

- Training personnel on the practical application of these materials.

Impact

The project demonstrated how meticulous planning and precise instruction can significantly enhance maintenance outcomes. By fostering better communication and adherence to safety protocols, the initiative showcased the tangible benefits of structured engineering documentation in complex industrial settings.

This project highlights our capability to deliver high-quality structural drafting solutions tailored to our clients’ needs.