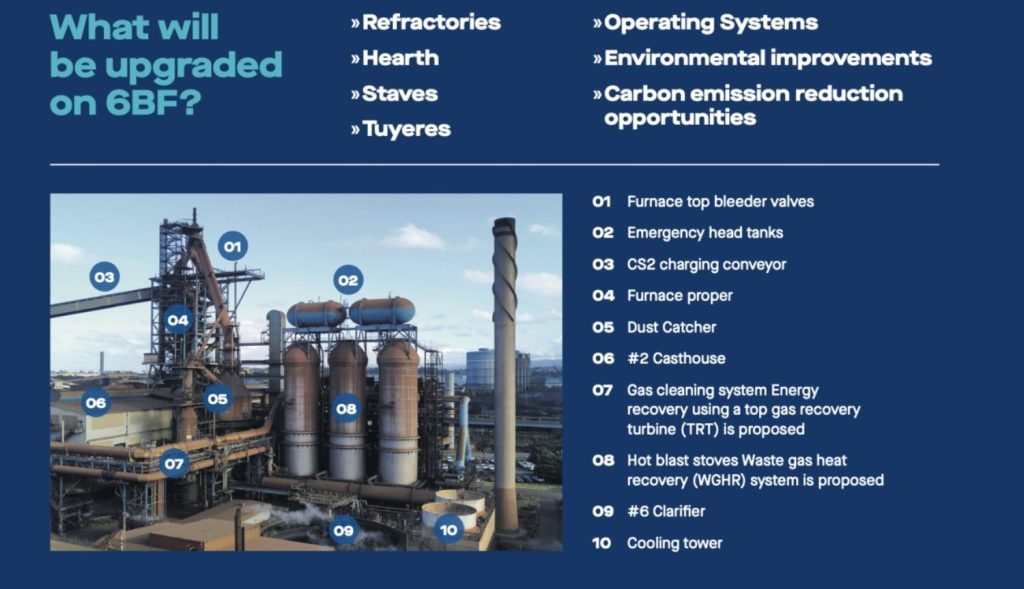

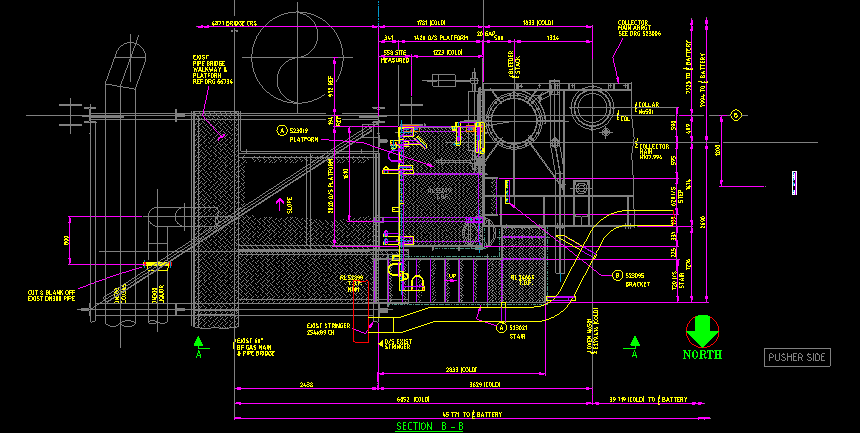

The BlueScope Steel Coke Plant No.6 Maintenance Project demonstrated our ability to deliver exceptional results in a collaborative environment. Partnering with L.E. Otten, a renowned engineering consultancy, this project focused on the 3D modelling of the furnace modification area and the development of detailed installation and manufacturing drawings.

Project Highlights:

- 3D Modelling: Advanced CAD tools were employed to create precise visualizations of the furnace modification area. This comprehensive modelling facilitated the identification of potential design and installation challenges, allowing preemptive solutions.

- Installation and Manufacturing Drawings: The detailed drawings derived from the 3D models served as essential guides for contractors, ensuring accurate execution of modifications.

- Streamlined Communication: The utilization of 3D modelling enhanced communication among stakeholders, aligning goals and expectations throughout the project lifecycle.

- Cost and Time Efficiency: Identifying potential issues early reduced downtime and avoided costly errors, ensuring the project was delivered on schedule and within budget.

- Safety and Quality Assurance: By addressing problems before implementation, the project team achieved higher safety standards and superior quality outcomes.

Scope of Work:

- Identifying and resolving potential design issues.

- Generating accurate installation and manufacturing drawings.

- Procuring materials and equipment for the furnace modifications.

- Overseeing construction, testing, and commissioning processes.

The integration of 3D modelling and precise documentation proved critical to the project’s success, enabling seamless execution and highlighting the value of modern engineering practices.

This project stands as a testament to our commitment to innovation, collaboration, and excellence in delivering engineering solutions. It exemplifies how advanced technologies and meticulous planning can enhance project outcomes and drive efficiency.