Implementing in-house manufacturing requires meticulous planning, substantial resources, and a strategic vision. Businesses need to assess various factors to ensure the transition is viable and sustainable. Below is a more detailed breakdown of the requirements for setting up an effective in-house manufacturing operation:

1. Infrastructure

Facilities

- Land and Building: Securing a suitable location with enough space for production, storage, and potential future expansion. This includes considerations for zoning laws and proximity to suppliers and markets.

- Utilities: Adequate access to water, electricity, gas, and internet connectivity is vital for smooth operations. Backup systems, like generators, may be needed to avoid downtime.

Machinery and Equipment

- Production Machinery: Acquiring machinery specific to the product, whether it’s CNC machines for precision components or large-scale assembly lines for mass production.

- Maintenance: Regular upkeep and repair schedules to minimise downtime and ensure machinery longevity.

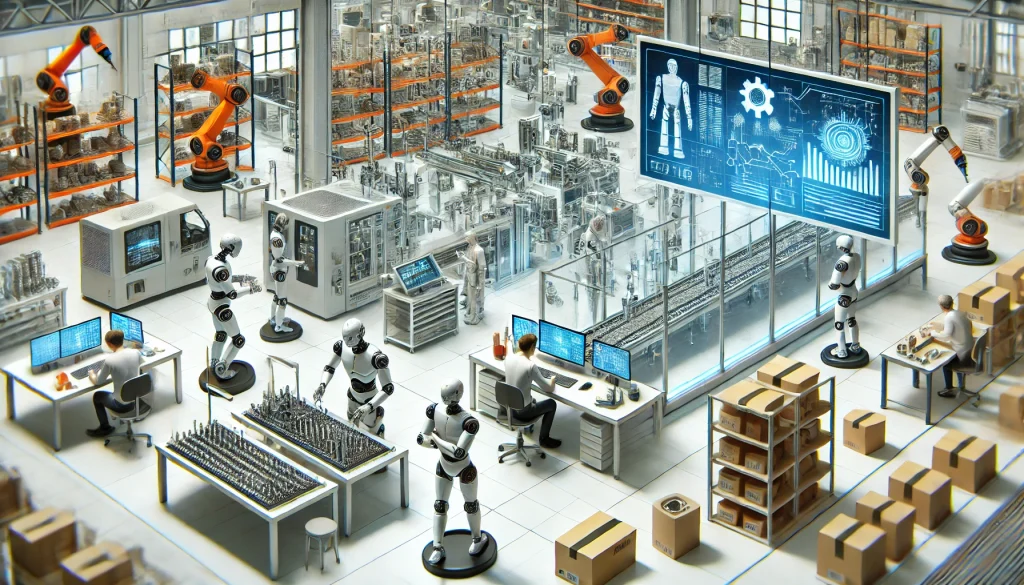

- Technology Integration: Leveraging advanced tools such as automation, robotics, and IoT (Internet of Things) for streamlined processes and real-time monitoring.

Safety Compliance

- Ensuring compliance with Australian occupational health and safety regulations (OHS) to protect workers and reduce liability.

- Installing fire safety systems, proper ventilation, and ergonomic workspaces.

2. Labour Force

Skilled Workforce

- Recruitment: Hiring skilled operators, technicians, and engineers capable of handling complex manufacturing processes.

- Training: Offering regular training to ensure workers stay updated with the latest technologies and practices. For instance, training programs for operating CAD/CAM systems can be critical for precision manufacturing.

Management Team

- Employing managers and supervisors to oversee operations, maintain schedules, and ensure quality control.

- Human resource teams to handle recruitment, payroll, and compliance with Australian workplace regulations.

Labour Laws and Policies

- Adhering to Australian labour laws, including minimum wage, working hours, and employee benefits.

- Developing a safe and inclusive work culture to enhance productivity and retain talent.

3. Expertise

Technical Knowledge

- Businesses must master production technologies, such as additive manufacturing, injection molding, or assembly line operations, depending on their product.

- Understanding industry standards and certifications, such as ISO 9001 for quality management or ISO 14001 for environmental management.

R&D Capabilities

- Establishing a research and development (R&D) department to innovate and refine products and processes.

- Testing facilities for quality assurance and product performance evaluations.

Supply Chain Expertise

- Developing efficient procurement strategies to source raw materials at competitive rates.

- Establishing relationships with reliable suppliers and logistical partners to avoid disruptions.

4. Regulatory Compliance

Permits and Licenses

- Securing necessary permits and licenses, such as environmental clearances and industry-specific approvals, from Australian regulatory bodies.

Product Standards

- Ensuring that products meet Australian Standards (AS) or other international benchmarks where applicable.

Environmental Regulations

- Implementing eco-friendly practices, such as waste recycling and energy-efficient production methods, to comply with environmental laws and boost sustainability.

5. Financial Investment

Initial Costs

- Significant capital is needed for land acquisition, machinery, and infrastructure setup. For instance, a precision tooling facility might require millions in upfront investment.

- Budgeting for contingencies to handle unexpected delays or cost overruns.

Operational Costs

- Ongoing expenses such as utilities, raw materials, labour, and maintenance.

- Allocating funds for marketing, distribution, and customer support to drive sales.

Financing Options

- Exploring loans, grants, or partnerships to ease the financial burden. For example, Australian government initiatives may offer funding for manufacturing startups.

6. Technology Integration

Production Software

- Employing ERP (Enterprise Resource Planning) systems for inventory management, production scheduling, and financial tracking.

- CAD/CAM software for design and prototyping.

Automation and AI

- Incorporating automated processes, such as robotic arms or AI-powered quality checks, to improve efficiency and accuracy.

Data Security

- Setting up robust cybersecurity measures to protect intellectual property and sensitive business data.

7. Market and Demand Validation

Feasibility Study

- Conducting market research to understand customer needs and assess demand trends.

- Identifying key competitors and analysing their manufacturing strategies.

Pilot Production

- Running small-scale pilot projects to validate processes and gauge market response before scaling up.

Distribution Channels

- Establishing reliable distribution networks to ensure timely delivery of products to customers.

8. Sustainability Practices

Energy Efficiency

- Investing in renewable energy sources, such as solar panels, to reduce operational costs and environmental impact.

Waste Management

- Developing strategies to recycle production waste or repurpose by-products.

Green Certifications

- Obtaining certifications, such as GreenTag or GECA, to appeal to environmentally conscious consumers.

In-house manufacturing requires a significant commitment of resources, but it offers unparalleled control, flexibility, and potential profitability. Businesses should carefully assess their capabilities and conduct a detailed cost-benefit analysis to determine whether in-house production aligns with their goals. By focusing on infrastructure, labour, expertise, and compliance, Australian companies can build robust manufacturing operations that drive innovation and growth.