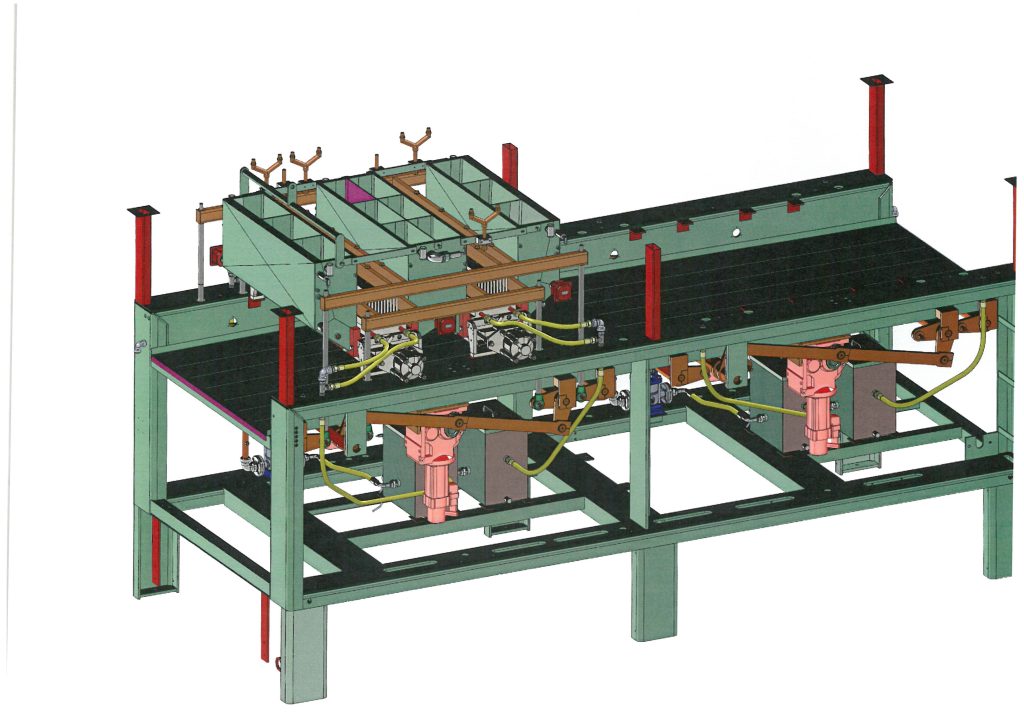

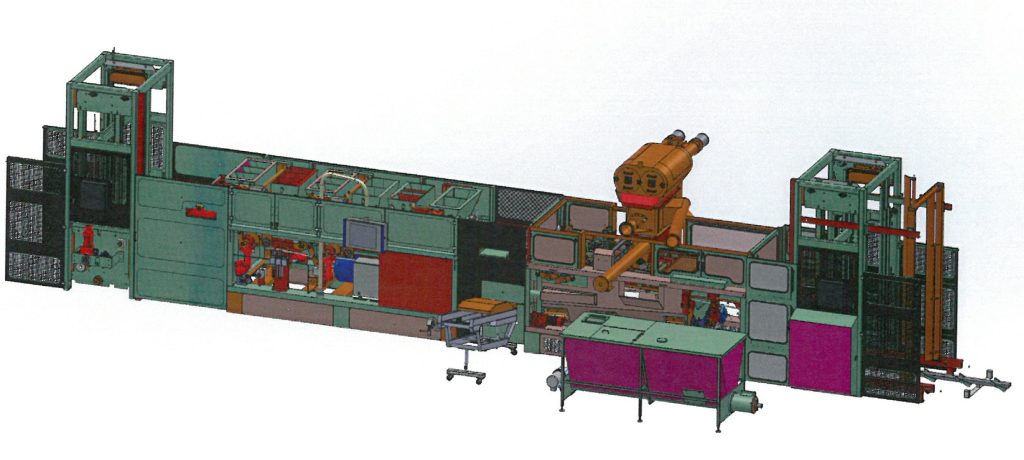

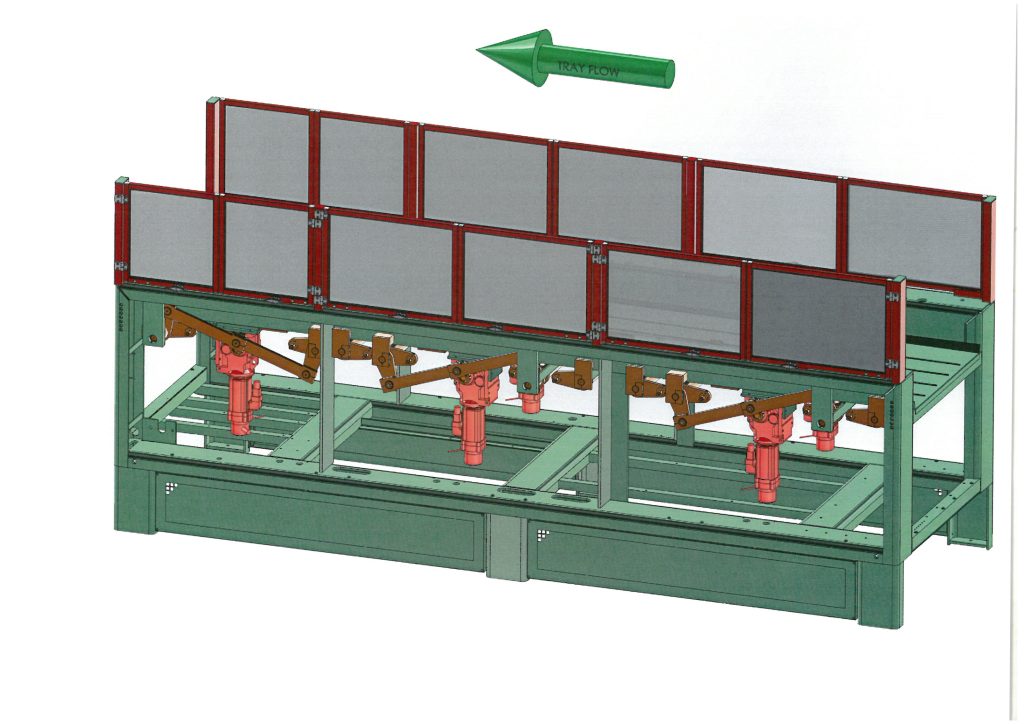

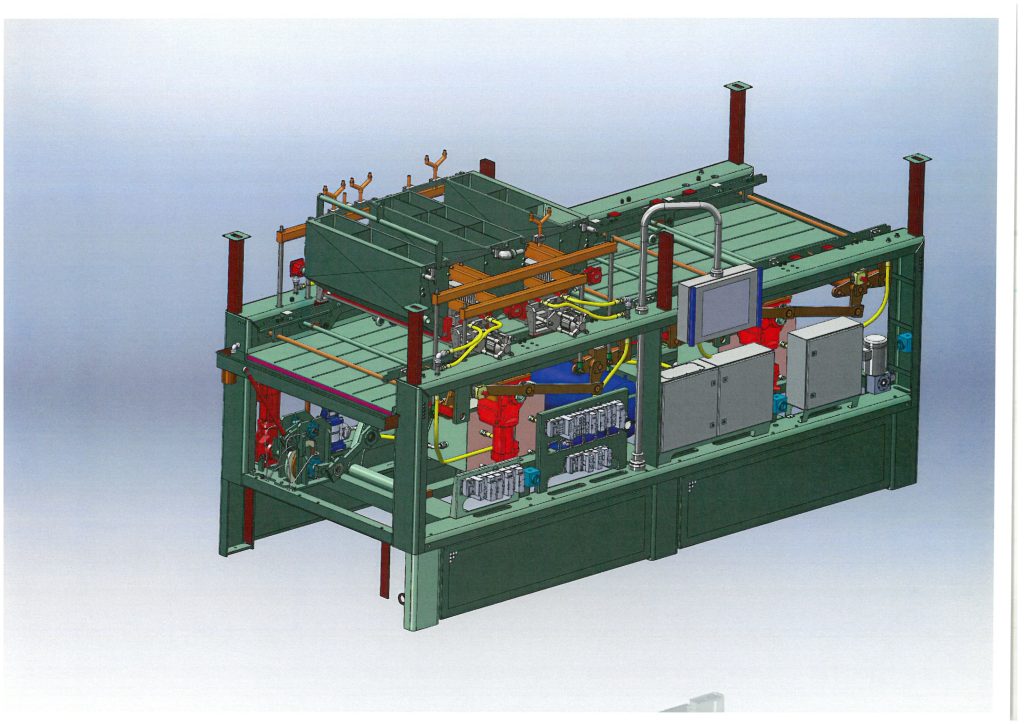

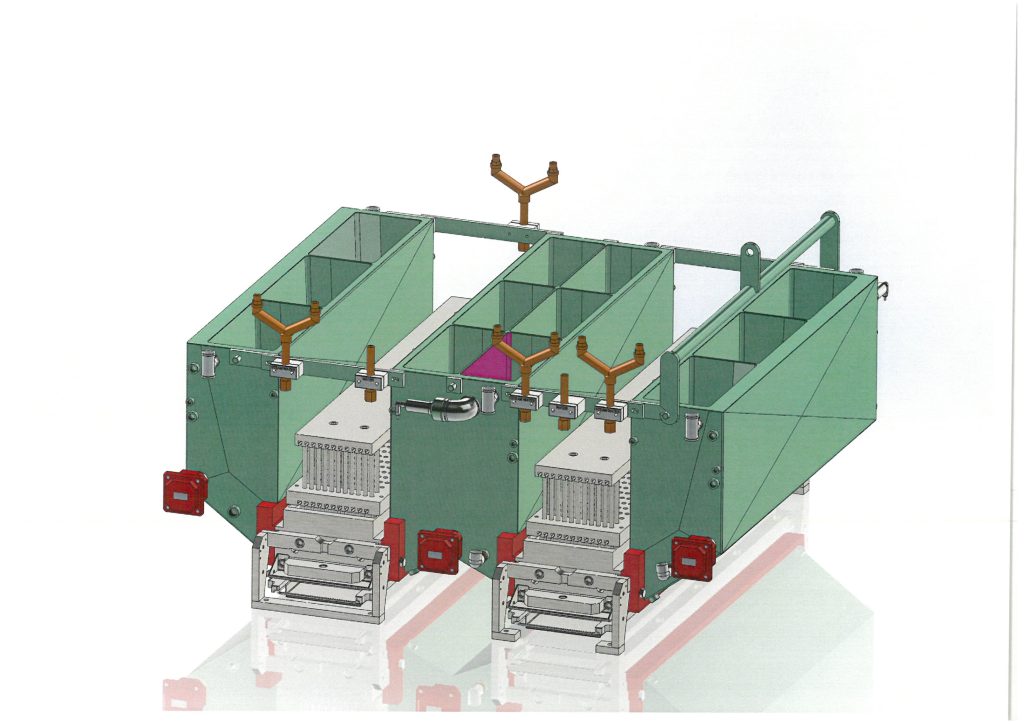

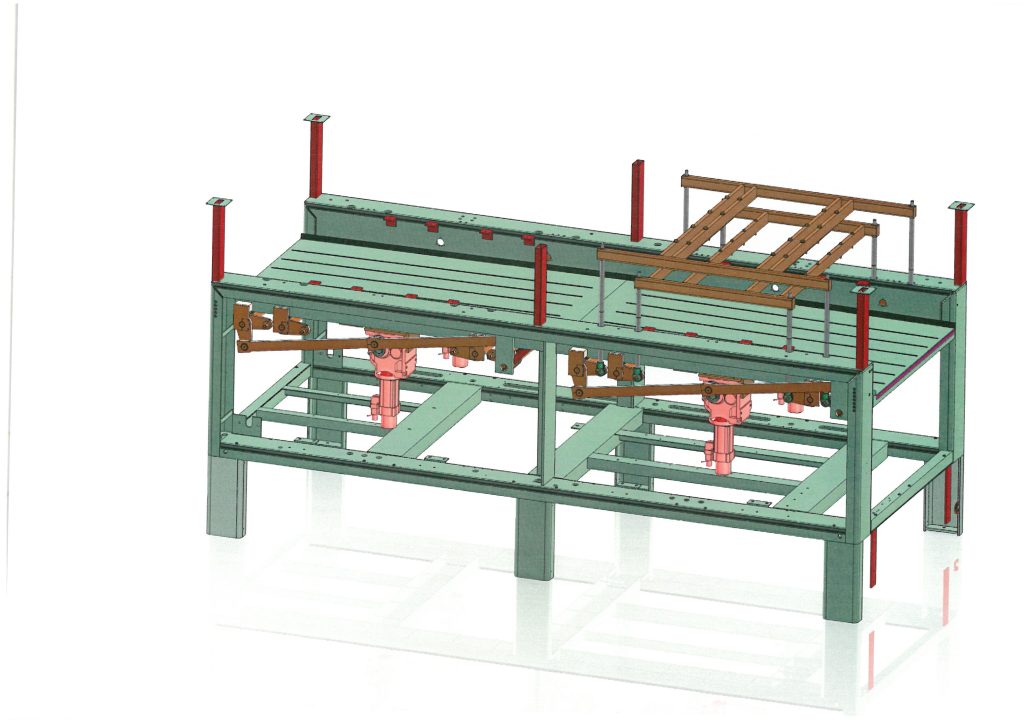

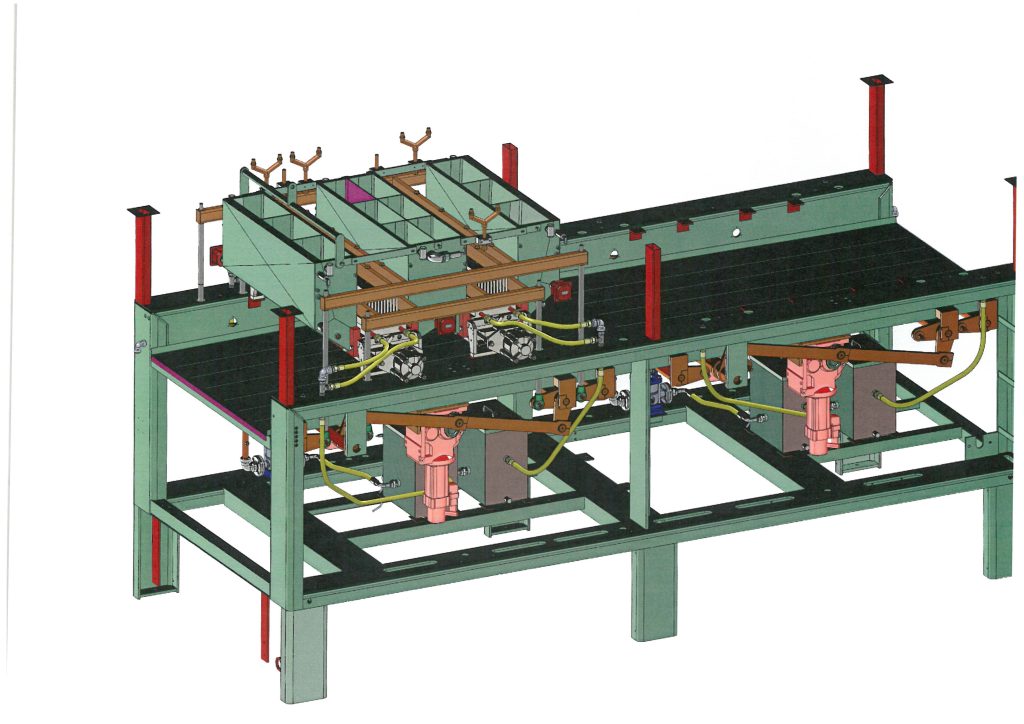

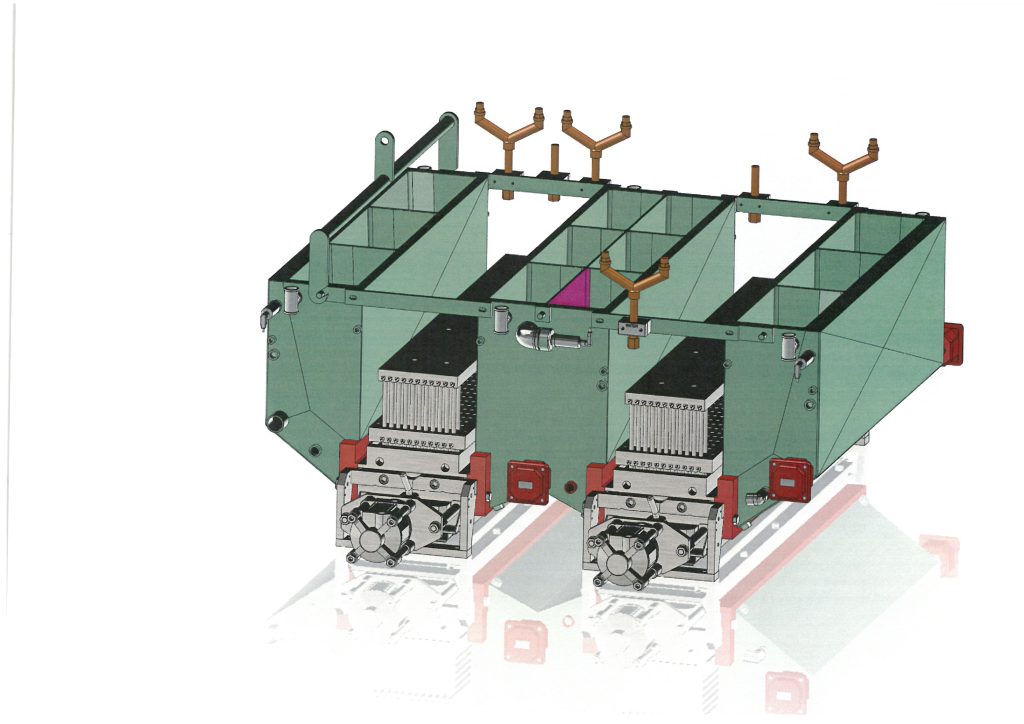

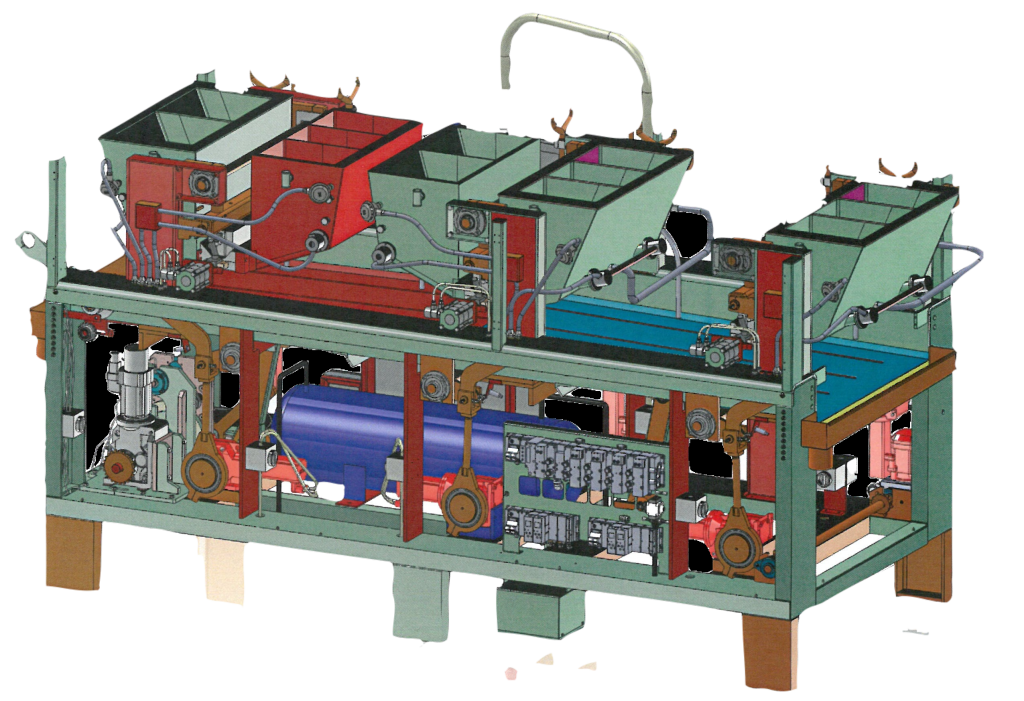

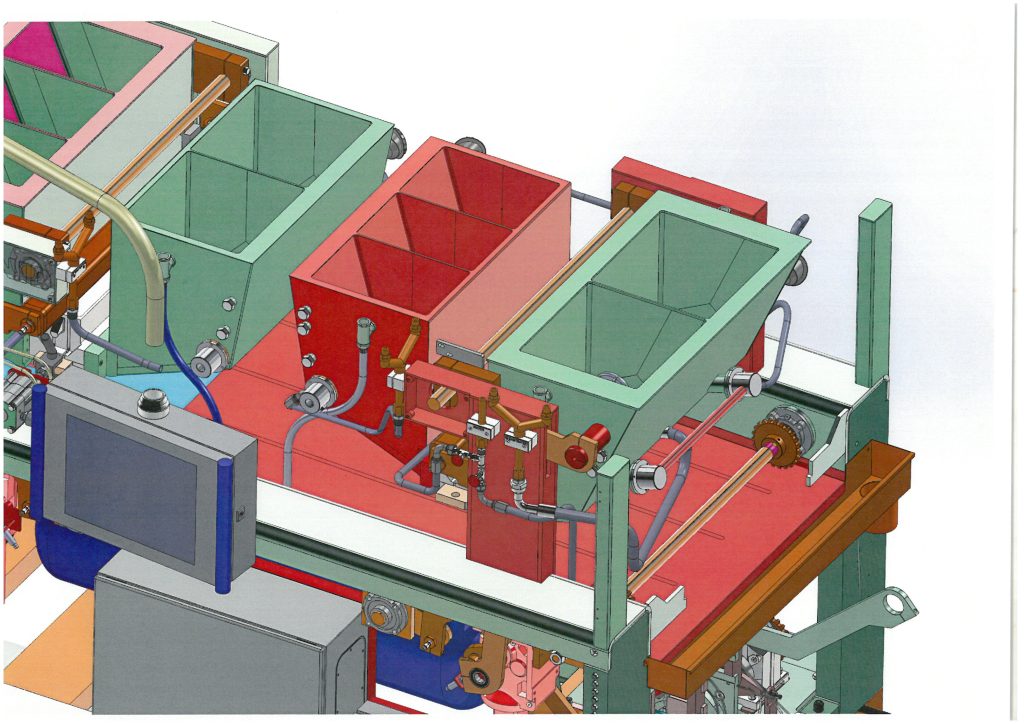

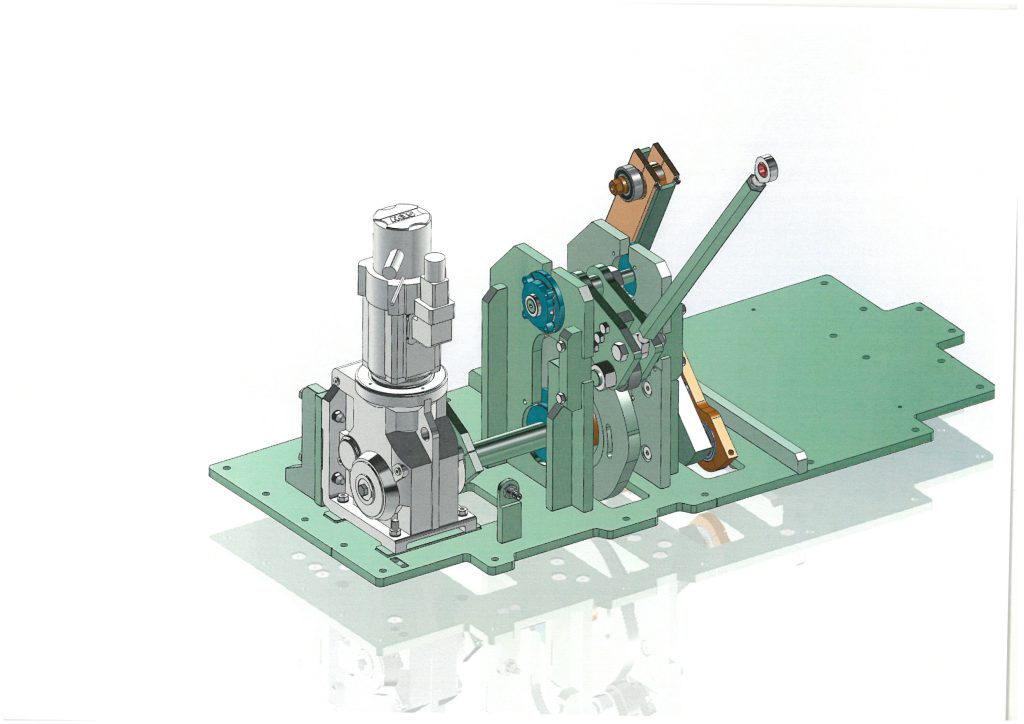

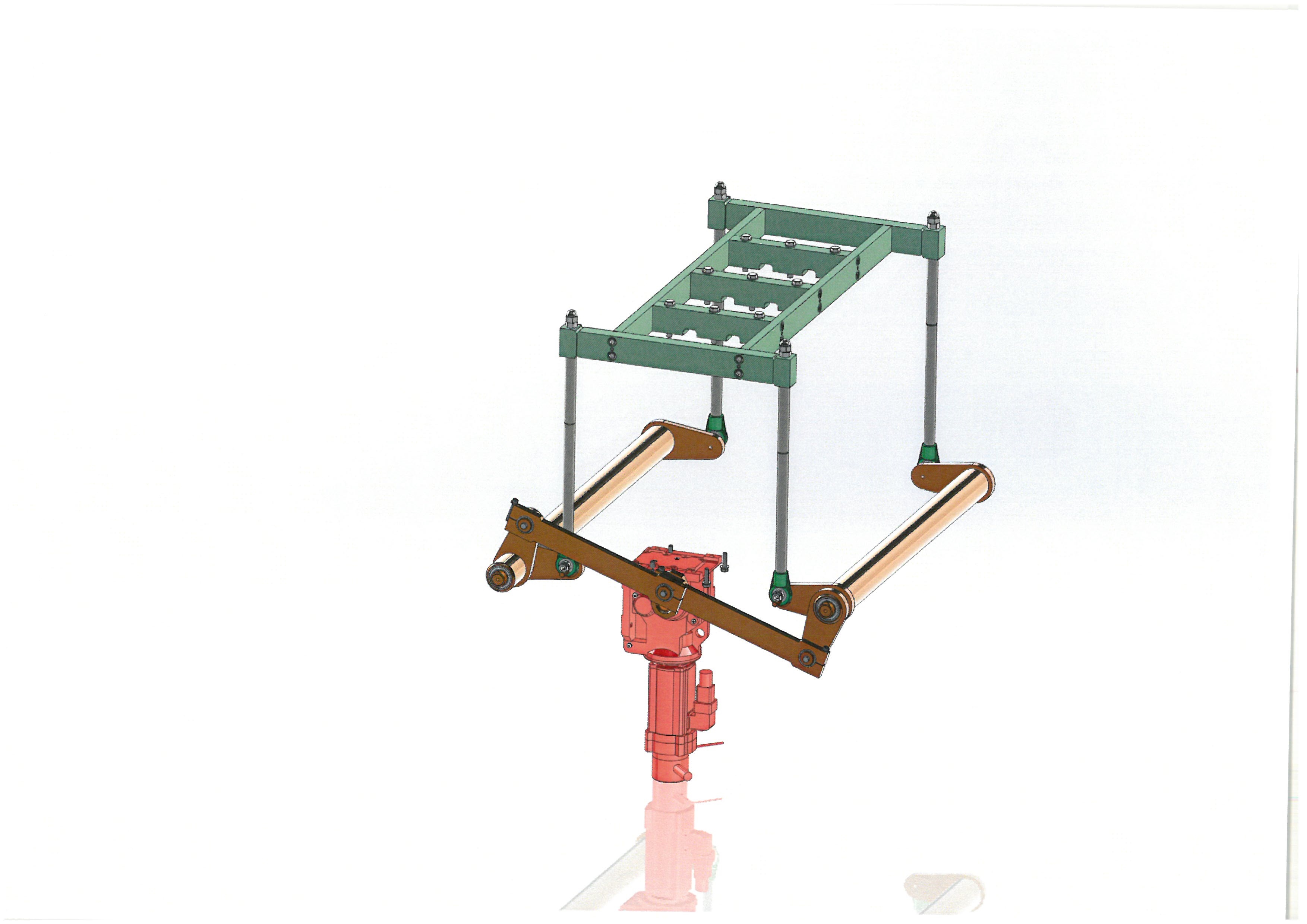

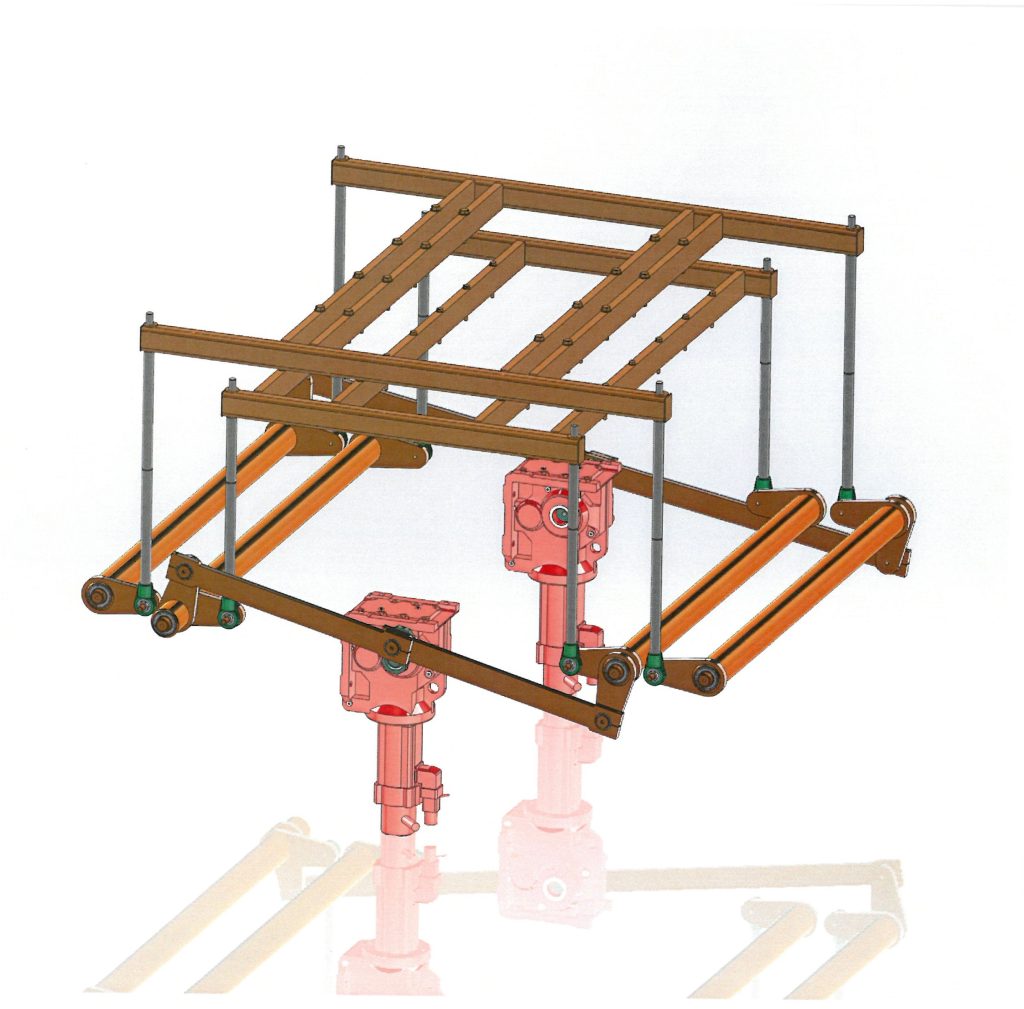

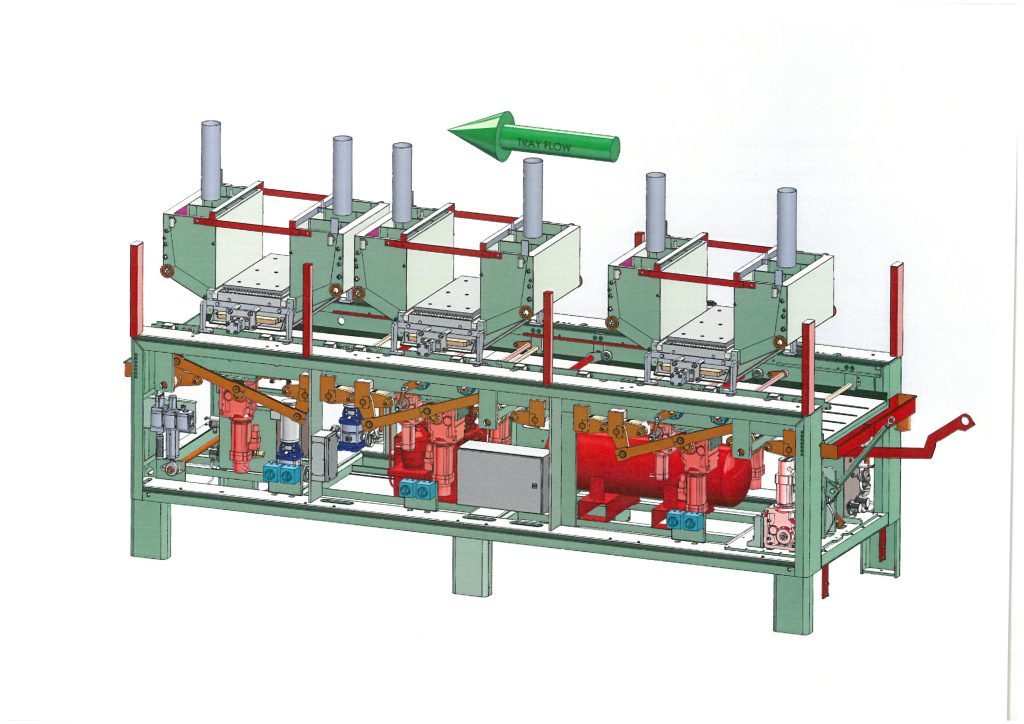

We collaborated with NID PTY LTD on multiple special purpose machine building projects, delivering tailored solutions for various industries such as food, pharmaceutical, and cosmetics. Our team designed and constructed machines customized to meet the unique requirements of each client. Among the notable projects were:

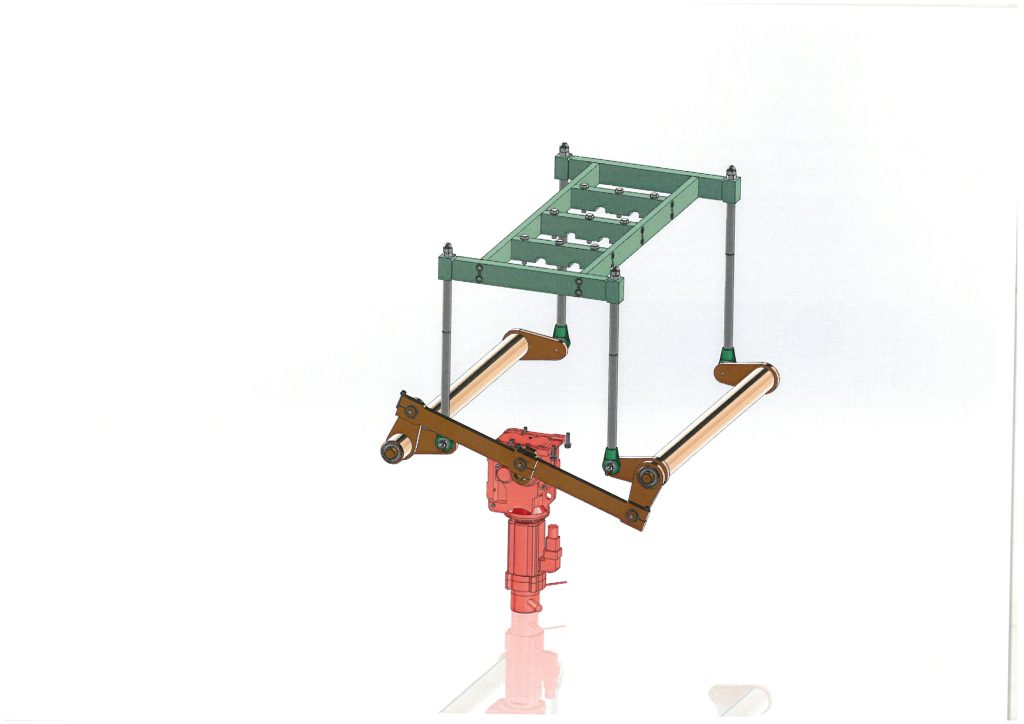

- A swing hopper depositor for Nature’s Product.

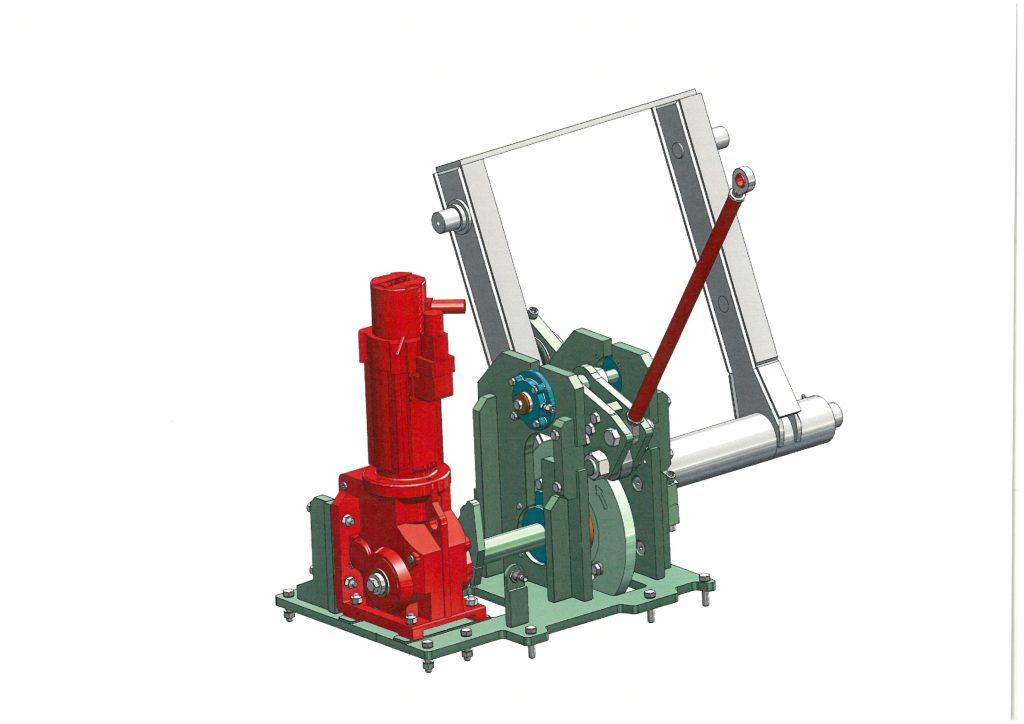

- High-speed depositors processing 35-40 trays per minute for companies including Tigerbrands, Pharmavite, Sweetcandy, Santacruz, Church and Vite, and Interpack.

Challenges and Solutions

These projects presented several engineering challenges, including:

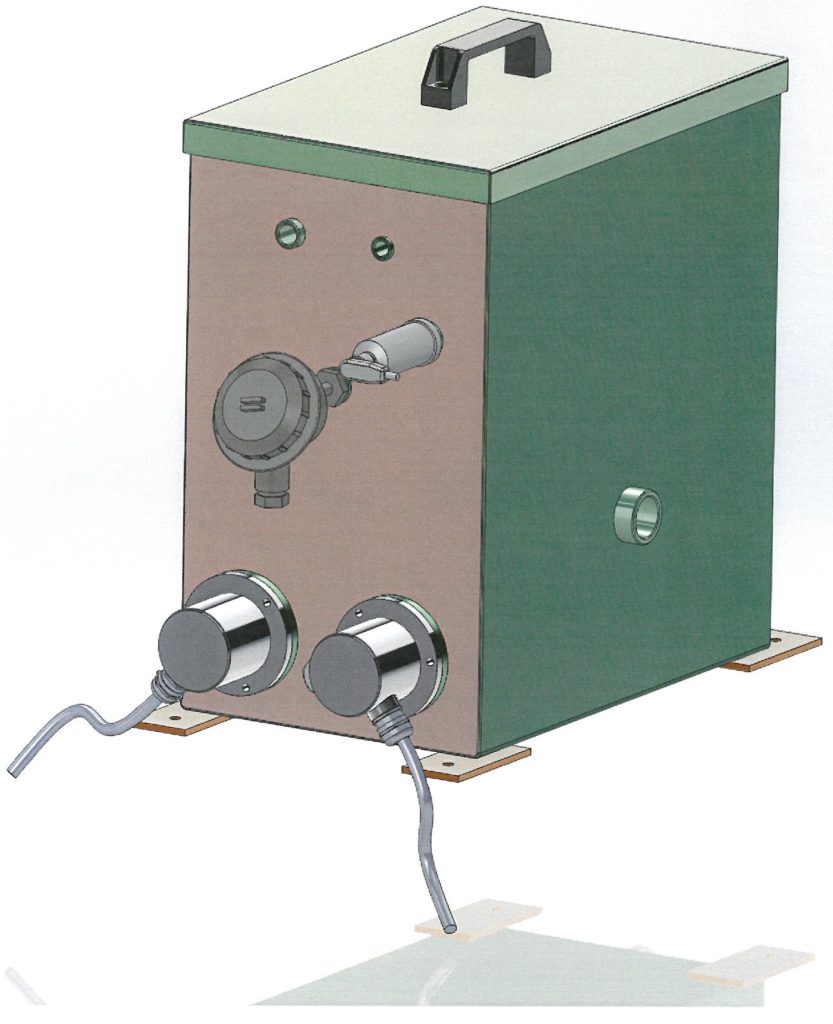

- Customization Needs: Machines required highly specific configurations to cater to diverse operational requirements.

- High-Speed Operations: Ensuring precision and reliability at elevated speeds.

- Product Versatility: Designing systems capable of handling a variety of products with flexibility and efficiency.

The challenges were addressed through in-depth engineering expertise and close collaboration with clients throughout the project lifecycle.

Outcomes

The resulting machines significantly enhanced the productivity of clients and supported the production of high-quality products. Each solution was engineered with precision and built to perform reliably in demanding industrial environments.

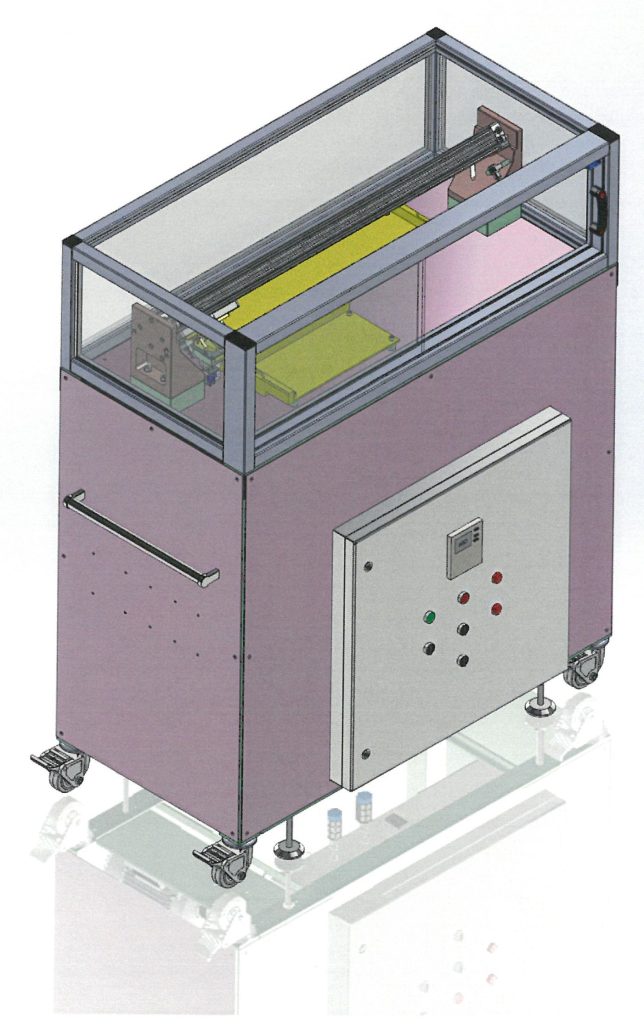

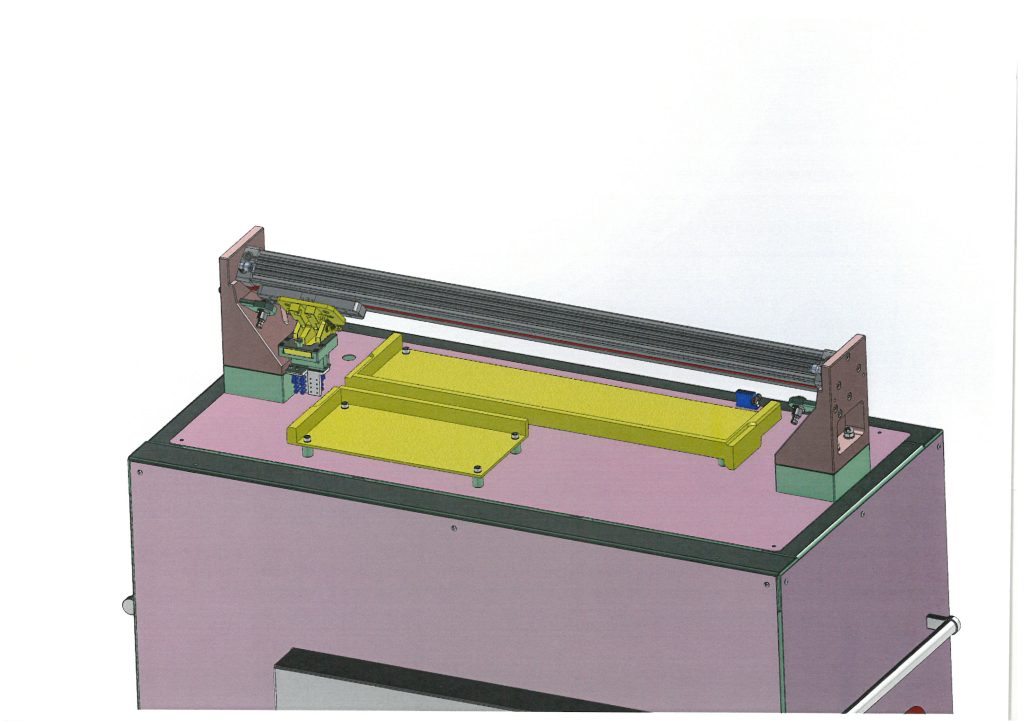

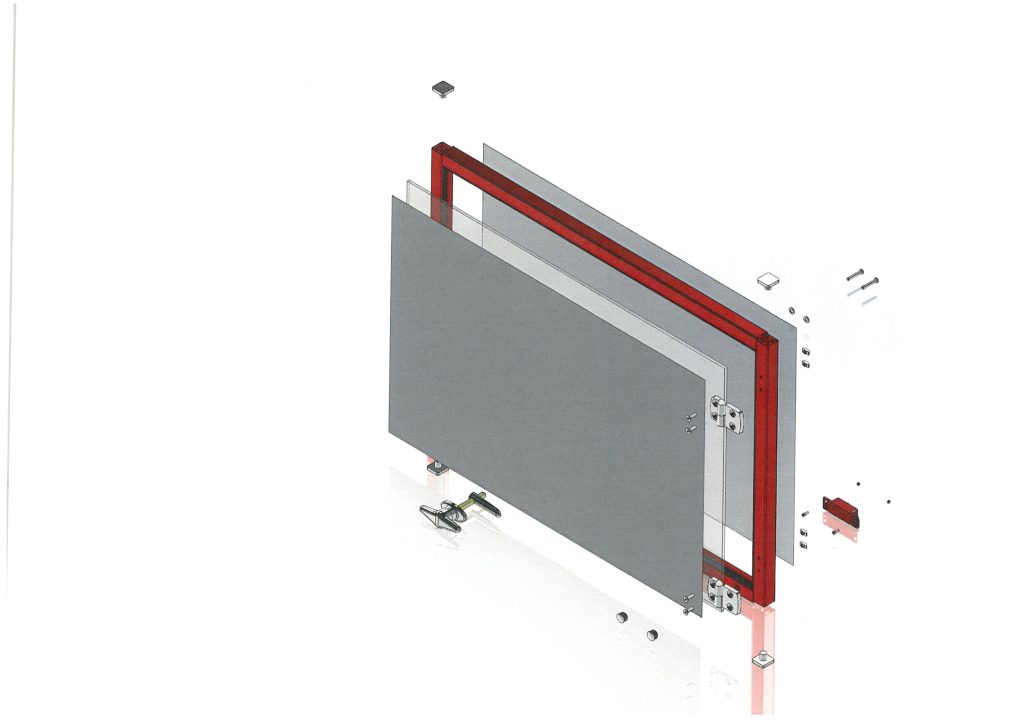

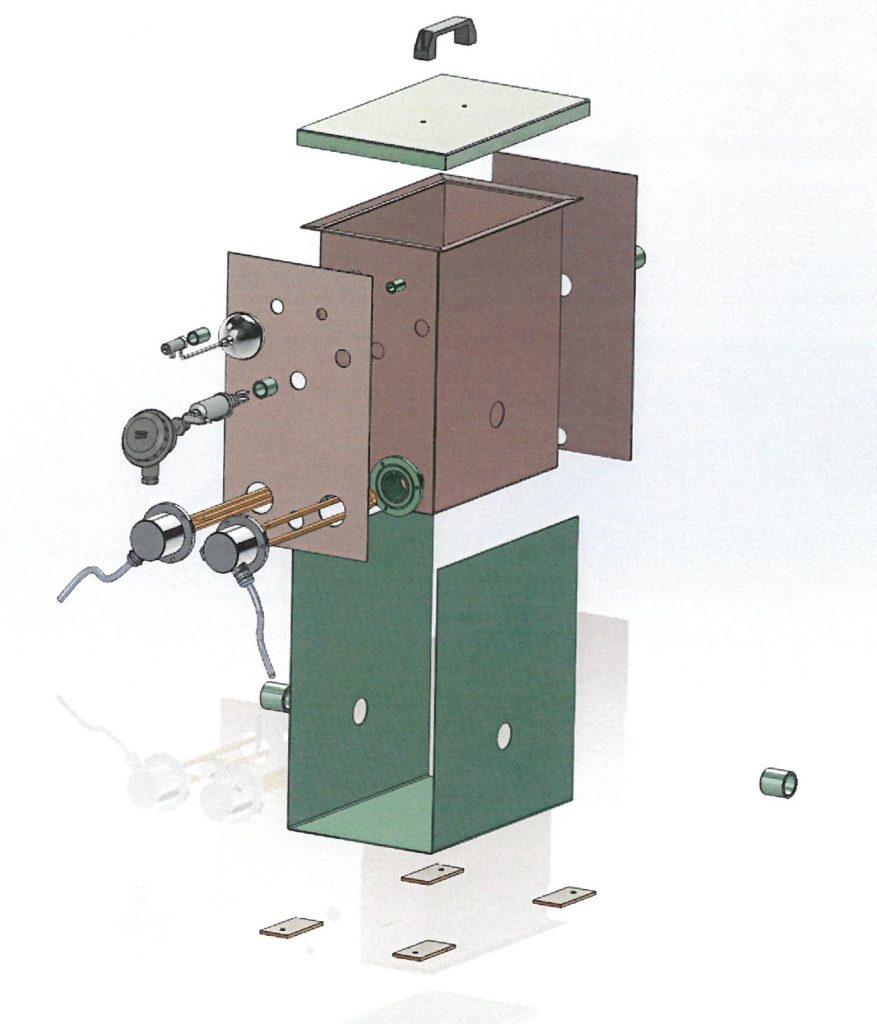

Images showcasing project highlights have been provided to illustrate the scope and quality of the work.